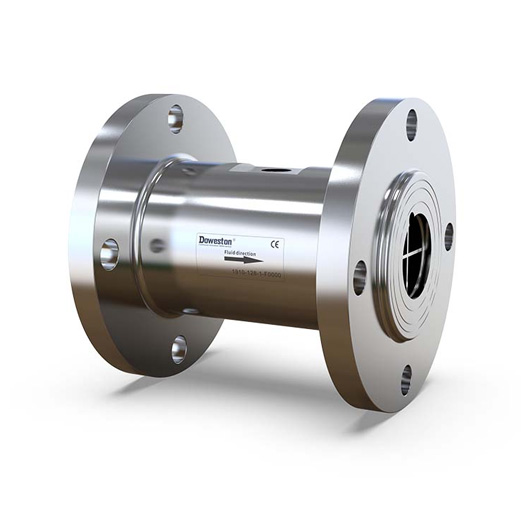

FTR-1600F flanged turbine flowmeter basic principle: fluid flow through the sensor shell, because the impeller blade and flow direction has a certain angle, the impulse of the fluid to the blade has a rotational torque, after overcoming the friction torque and the fluid resistance, the blade rotates, the speed is stable after the torque balance, under certain conditions, the speed is proportional to the flow speed, because the blade has the magnetism, it is located in the magnetic field of the signal detector (composed of magnet steel and coil) . The rotating blades cut the magnetic lines of force, periodically changing the magnetic flux of the coil, thus causing an electrical pulse to be induced at both ends of the coil, the signal is amplified and shaped by the amplifier to form a certain amplitude of continuous rectangular pulse wave, which can be transmitted to the display instrument, showing the instantaneous flow and the cumulative amount of fluid. Within a certain range of flow rate, the pulse frequency f is proportional to the instantaneous flow rate q of the fluid flowing through the sensor.

The pressure loss is small, the impeller has the anticorrosion function

The use of advanced ultra-low power consumption single-chip microcomputer technology, the whole machine function is strong, low power consumption, superior performance

Intelligent flow indicator with nonlinear accuracy compensation function. The accuracy of the modified formula is better than ± 0.02%

The cumulative flow and instrument coefficient power-off protection with EEPROM is adopted, and the protection time is more than 10 years

The use of high-performance MCU central processor, complete data acquisition and processing display output, cumulative flow instantaneous flow display at the same time

The amplifier can be separated from the sensor (separation distance 15m)

With strong anti-magnetic interference and vibration ability, reliable performance and long life

Corrosion resistance, suitable for acid-base solutions

Lower limit flow rate is low and the measuring range is wide

Can be made into insert type, suitable for large-caliber measurement, low pressure loss, low price, can flow out, easy installation and maintenance.

The scope is wide, the medium and large caliber can reach 1:20 and the small caliber 1:10

Application: FTR-1600F flanged turbine flowmeters are widely used to measure the volume flow and total volume of low viscosity liquids in closed pipelines. It is widely used in petroleum, chemical industry, metallurgy, city gas pipeline network and other industries.