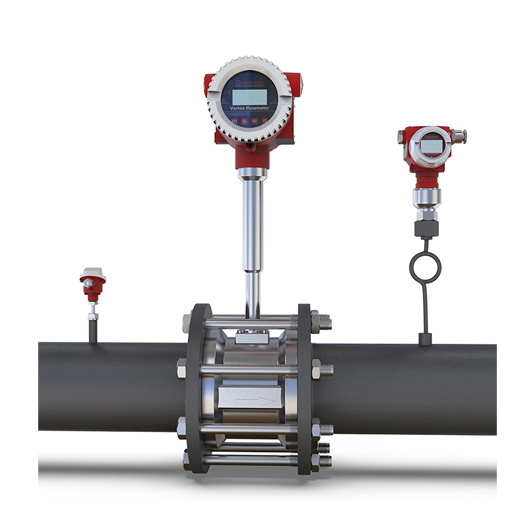

The basic principle of the ftv-1600 double system vortex flowmeter is the Carmen vortex phenomenon. When a medium flows through a triangular cylinder-shaped vortex generator at a certain speed, two alternating rows of vortices are formed on either side, the vortex is called the Kármán Vortex Street. Strouhal built on the Carmen vortex theory by suggesting that the frequency of the Carmen vortex is proportional to the velocity of the fluid. And with temperature and pressure compensation and integrator combined into a double system, more stable and reliable, perfect data retention.

Corrosion-resistant stainless steel material, ABS full mold production probe, simple structure.

The detection sensor does not directly contact the measured medium, the performance is stable, and the life is long.

The output is a pulse signal proportional to the flow, without zero drift and with high precision.

Low pressure loss, low operating cost, more energy-saving significance.

The volumetric and mass flow rates of steam, gas and liquid can be measured.

The amplifier can be separated from the sensor (separation distance 15m) .

The use of noise elimination circuit and anti-vibration sensor head, so that the instrument has a certain anti-environmental vibration performance.

The pressure loss is small, the range of measurement is wide, the range is 10-40 times.

The temperature of the measurable medium reaches + 350 ° C

No mechanical moving parts, long-term stability, simple structure for installation and maintenance.

The output of the sensor is a pulse frequency, its frequency is linear with the actual flow of the measured fluid, zero drift, performance is very stable.

The adoption of RS-485 communication, or Hart communication, can realize factory automation, integration.

Application:

FTV-1600 double system vortex flowmeters are widely used to measure volume and mass flows of superheated steam, saturated steam, Compressed air and general gases and liquids.